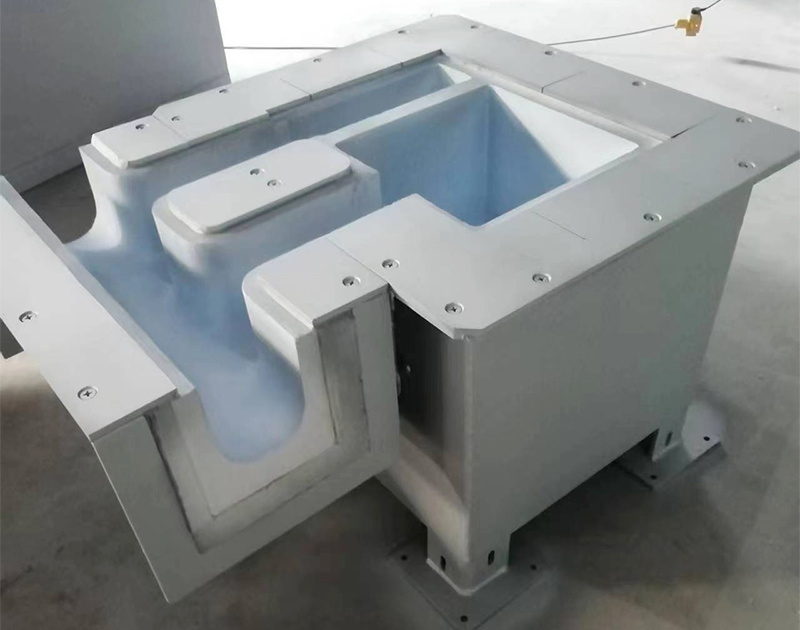

Prefabricated refractory components

Boronide Company can provide customers with various prefabricated refractory materials according to the drawing requirements, including degassing box lining, filter box lining, launders lining, and other non-standard components.

BRC refractory clay is a material used for stacking and repairing refractory materials, and is widely used for the maintenance and repair of aluminum melt casting molds, launders, boxes bodies, nozzles, and other parts. It has the characteristics of good plasticity,high bonding strength, strong corrosion resistance, and good slag invasion resis-tance.

BFC-30 launder coating is a water-based environmental release coating,which does not contain Volatile organic compound. Apply to the surface of launders,diversion plates, filter boxes, etc., to facilitate dealumination and extend the service life of refractory materials.

Nanometre graphite emulsion lubricant

This product uses a supercritical stripping device to process high-purity graphite to the nanoscale, obtaining extremely fine graphite particles that are more evenly dispersed in aqueous solution, thereby obtaining a higher water to water ratio. Nowadays, more and more aluminum plate enterprises choose to increase casting and rolling speed to increase production capacity without expanding their production lines. Traditional smoke carbon lubrication can no longer meet the requirements of casting and rolling speed. As a water-based graphite emulsion,BNG-P50 has advantages such as high efficiency and environmental protection, which can provide effective lubrication for improving casting and rolling speed and prevent aluminum plate adhesion.

Liquid separator for Aluminum extrusion

BAE aluminum extrusion liquid separator is a water-based high temperature resistant release spray. All compo-nents of the product are completely water-soluble, and have very good lubrication effect and high temperature stabil-ity. When used in the aluminum extrusion process, it can effectively prevent aluminum alloy from sticking to extrusion tools under high temperature, improve production efficiency, and at the same time, it will not pollute aluminum prod-ucts and the environment.

Aluminum extruded solid lubricating rod

Boron nitride aluminum extrusion solid lubricating rod is a white rod-shaped solid, which has good high-temperature stability and lubrication performance. It can be applied to areas such as extrusion pads, ingotcon-ntainers, and residual shear, effectively preventing aluminum alloy from sticking to the mold, extending the lifespan of the extrusion pad, making it easy to use, shortening maintenance time, improving production efficiency, and saving costs. Smoke less, do not contain dangerous ingredients, and are harmless to human health.

Aluminum extrusion release agent spraying equipment

During the aluminum extrusion process, there may be adhesion between the pressure residue and the extrusion pad. Cleaning the pressure residue and reinstalling the extrusion pad can reduce the extrusion efficiency and increase the workload of the operator. Spraying isolation agents can effectively solve this problem。Unlike traditional manual spraying extrusion pads,BAS-330/330a automatic spraying equipment can be installed next to the transmis- sion track of the short rod, achieving automatic spraying of the aluminum rod end face, reducing manual intervention,improving spraying efficiency, and effectively reducing the amount of isolation agent used.

Aluminum extrusion release agent spraying equipment

During the aluminum extrusion process, there may be adhesion between the pressure residue and the extrusion pad. Cleaning the pressure residue and reinstalling the extrusion pad can reduce the extrusion efficiency and increase the workload of the operator. Spraying isolation agents can effectively solve this problem。Unlike traditional manual spraying extrusion pads,BAS-330/330a automatic spraying equipment can be installed next to the transmis- sion track of the short rod, achieving automatic spraying of the aluminum rod end face, reducing manual intervention,improving spraying efficiency, and effectively reducing the amount of isolation agent used.

Boron nitride water based release spry

BAE-BNS is a water-based BN spray release agent,applied in aluminum extrusion process, playing a role in lubrication and isolation.This product uses nanometer hexagonal Boron nitride. Compared with the traditional aluminum extrusion release agent, this product can be used at a temperature of more than 500 ℃ without smoke, dust, etc., which can effectively prevent the extrusion head from sticking to the aluminum rod,and has high water solubility, convenient cleaning, no pollution to the product, and has the advantages of lubrication, efficiency and environmental protection.