BND Material Technology

It is a high-tech enterprise specializing in the research and development, production, sales and technical services of molten metal high-end auxiliary materials and related equipment.

The company has 2 imported boron nitride coating production lines, with an annual shipment exceeding 60 tons, 1 aluminum extrusion lubricating rod production line, with an annual output of more than 50,000 pieces; 1 aluminum extrusion release agent production line, with an annual output of more than 5,000 tons ; 1 high-temperature repair agent production line, with an annual output of more than 50 tons; 3 water-based casting coating production lines, with an annual output of more than 300 tons, and the main products have passed ISO9001 certification.

BND Material Technology

Liquid separator for Aluminum extrusion

Aluminum extruded solid lubricating rod

Aluminum extrusion release agent spraying equipment

Metal based Boron nitride coating

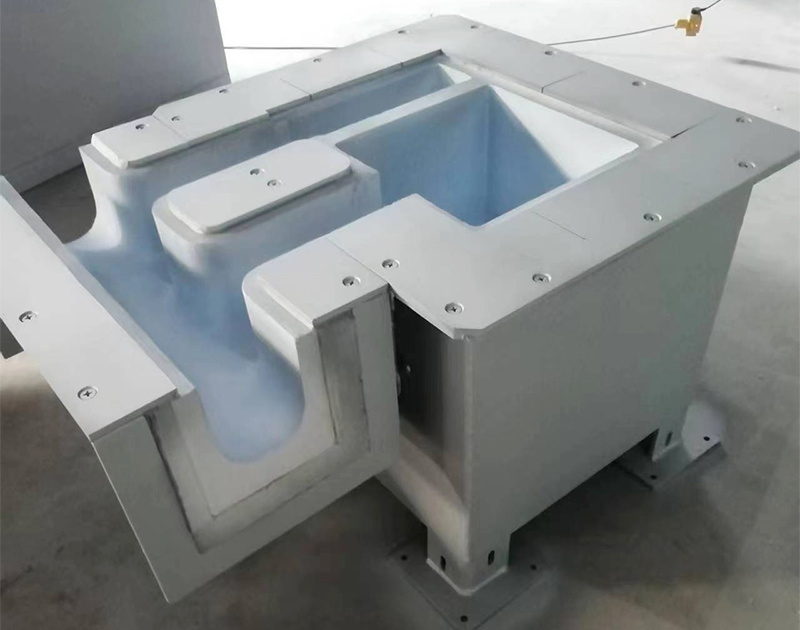

Prefabricated refractory components

Nanometre graphite emulsion lubricant

Boron nitride water based release spry

BND Material Technology

The 3rd China Guangzhou International Aluminum Industry Exhibition 2020

The 3rd 2020 China Guangzhou International Aluminum Industry Exhibition will be held in Guangzhou Pazhou International Purchasing Center on October 13-15, 2020

2017 Shanghai International Aluminum Expo

Specializing in molten metal auxiliary materials and related equipment research and development, production, sales

2019 Shanghai International Aluminum Expo

Professional sales and logistics team can provide customers with all-weather products and technical services

The 3rd China Guangzhou International Aluminum Industry Exhibition 2020

The 3rd 2020 China Guangzhou International Aluminum Industry Exhibition will be held in Guangzhou Pazhou International Purchasing Center on October 13-15, 2020